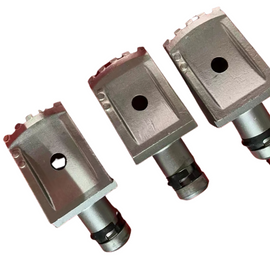

Bullet Teeth Holder

Part Numbers:

QC100 、QC110H 、QC187HD 、QC110HD、KPF303R 、CB10 、KPF400 、 KPL302 、C10LG 、C87 、CMB6

C10LG 、C87、 C10AMC 、CMB6、CMB4 、CMB5 、C10 、C10H 、SLB 、C10、C87B

Get Samples

Lead time:

| Quantity (pieces) | 1 – 50 | 50-3000 | > 3000 |

| Lead time (days) | 15 | 20 | 30 |

Purchase details

Payments: T/T, Credit Card,

……

……

Also we can make all kinds of holders according to customer’s sample or drawing.

If you need other models,

please contact us as well.

Holder for Road Milling Teeth

1. High -quality alloy steel, cold extrusion and temperature extrusion process

In the needs of alloys and convenient performance, develop molds and study new processes.

2. Fully automatic welding quenching integrated production line

The most advanced cut -to -teeth production line, combined with cutting tooth cleaning, alloy welding, tooth body quenching, overall ignition, overall rust -proof treatment is equal to one.

3. Fully -automatic wear -resistant layer welding equipment to improve impact resistance and wear resistance

In the truncorated tooth effect, some heap welded layers of 3-5mm thickness, raw materials are wear-resistant welded powder imported by the United States, and the hardness of the pile welded layer can reach HRC60 or more (conventional between HRC45-48).

4. Autonomous development of thermal treatment process, computer precise control

The quenching and recovery temperature and time are the best solutions for independent research and development and repeated experiments; accurately controlled by the computer, and increased the three -stage temperature real -time monitoring feedback system, ensuring the stability and evenness of the temperature, the interception with high hardness, uniform hardness of hardness, uniform hardness, uniform hardness The characteristics of strong abrasion resistance.

4. The overall rust -proof processing process

It has equipment that fully automatically completes the process of cutting tooth transmission, rust -proof solution spraying, and surface drying. Eventually, a effective rust -proof layer is formed on the surface of the intercepts, which can ensure that the product is not rusty for a long time.

5. Strict inspection to ensure that each product is boutique

Professional instrument detection products, the surface quality of the product, internal and external hardness, welding fullness, etc., independent inspection rooms and advanced monitoring equipment, including hardness meter, gold phase analyzer, and two -digit measuring instrument to ensure 100%boutique.

Detals of Picks Holder

Mining pick holder is a kind of pick holder specially used in mining fields such as mines or quarries. Because in these environments, it is often necessary to transmit high torque and high power, and the working conditions are relatively harsh, so special design and manufacture are required to meet these requirements.

Mining pick holders are usually made of high-strength alloy steel, cast iron and other materials, which have more wear-resistant, impact-resistant, and corrosion-resistant properties. At the same time, better heat dissipation and shock absorption will also be considered in the design to improve the reliability and service life of the entire system.

Since machinery and equipment in environments such as mines and quarries often need to operate continuously for long periods of time, mining pick adapters also need to be easy to maintain and replace in order to quickly resolve faults and maintain production efficiency.