Button Bit

Name: top hammer drill bits, threaded button bit, threaded drill bit, hard rock drilling bits, button drill bit, rock drill bits, mining drill bits

Model Number: R25, R28, R32, R35, R38, T38, T45, T51, GT60, ST58, ST68, SR28, SR35…

Material:Structural Alloy Steel, Tugestun Carbide

Drill diameter: 28mm~48mm

Key configuration: 4 buttons, 5 buttons, 6 buttons, 7 buttons, 8 buttons

Taper angle: 7°/11°/12°

Skirt/Skirt length: 50-55mm, 60-70mm, 75mm-80mm

Socket inner diameter: 22/23/25mm

Button Type: Ballistic/ballistic, spherical button/spherical button

Color: blue, red, yellow, black (or custom)

Packing: 50pcs or 100pcs wooden case or plastic box.

Get Samples Lead time:

| Quantity (pieces) | > 50 | 50-3000 | > 3000 |

| Lead time (days) | 15 | 20 | 30 |

Purchase details

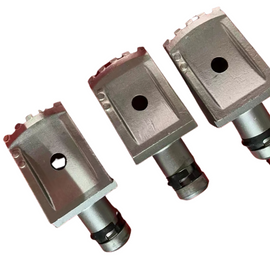

Product Display

Mining Drill Bits

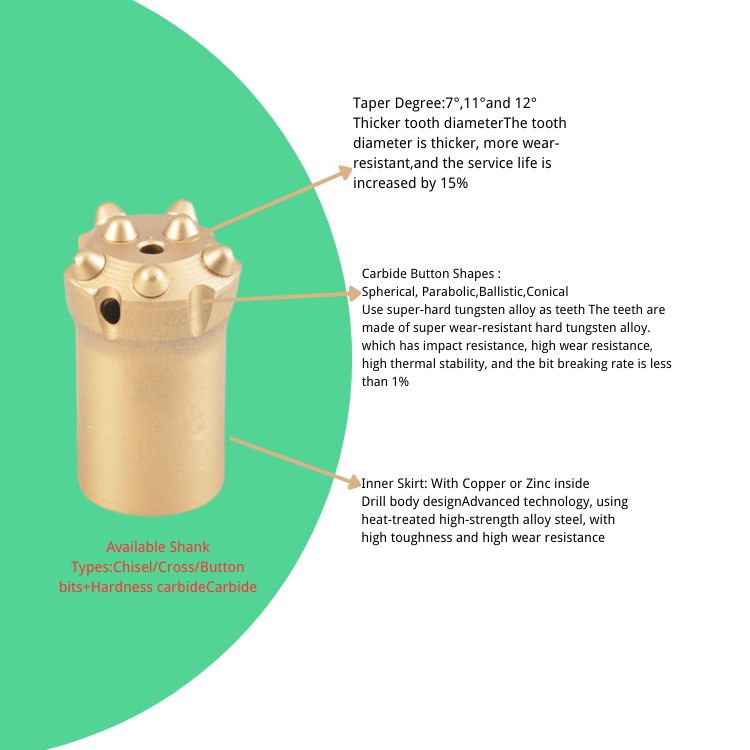

Degree:7°,11°and 12°

Carbide Button Shapes :

Spherical, Parabolic,Ballistic,Conical

Inner Skirt: With Copper or Zinc inside

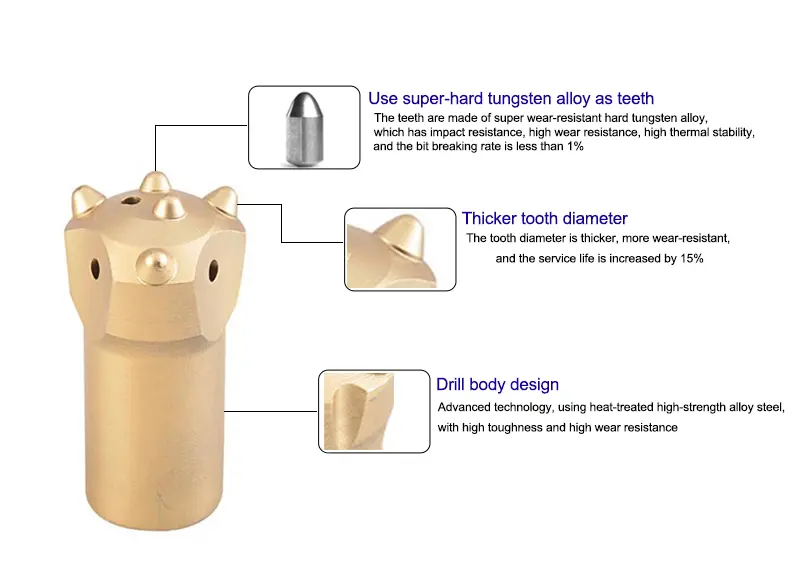

Drill Bit Teeth Tungsten Alloy Selection

SKYMECH use super-hard tungsten alloy as teeth

The teeth are made of super wear-resistant hard tungsten alloy, which has impact resistance, high wear resistance, high thermal stability. and the bit breaking rate is less than 1%

Thicker tooth diameterThe tooth diameter is thicker, more wear-resistant, and the service life is increased by 15%

Drill body design Advanced technology, using heat-treated high-strength alloy steel, with high toughness and high wear resistance

Why SKYMECH PDC Drill Bit

Our drill bits are made of high quality tungsten carbide and steel. After cold treatment, it can be used for drilling hard rock and transfer intense impact energy into the rock with minimal energy loss.

Impeccable design, tungsten carbide and skirted steel, leading strength and penetration, improved productivity, superior straightness and hole cleaning quality, maximized drilling performance and saved fuel costs.

According to customer samples or drawings design, manufacturing button diameter, button number, button punching, button shape, button Angle, etc.

Compared with tapered chisel bits and tapered cross bits, button bits have higher technology,

longer drilling time, and higher drilling efficiency. According to the different buttons, tapered button bits can be divided into dome type, ballistic type, etc.

Cone button bits are the most popular sharp bits available in a variety of head diameters from 26mm to 48mm.

Tapered button bits with hot pressed carbide buttons on the drill skirt have good drilling performance and excellent service life.

You May Like

FAQ

You can contact us at any time if you have questions about pdc drill bit、button bit、taper button bit、button drill bit、dth button bit、carbide button bit、button bit for rock drilling、button bit drilling、top hammer drill bits, threaded button bit, threaded drill bit, hard rock drilling bits, rock drill bits, mining drill bits or other products.

Yes, we are the source manufacturer here. As the source manufacturer, we personally purchase raw materials, and then strictly control the production link, quality inspection link and delivery link to ensure that the products can be delivered to customers with good quality and quantity.

If you have samples, you can provide them to us. We can test your samples through the equipment and then draw the drawings.

We can provide a small number of free samples, and customers bear the freight.

All our products are tested before delivery. If the buyer needs the test report, we can provide it. Including the raw materials used in this product, these can be detected.