Company Profile

As a professional custom metal processing factory, we have nearly 20 years of processing and trading experience. Escort your equipment in construction applications such as foundation drilling, Road reconstruction, Forestry & Recycling, trenching, etc.

Source manufacturers, affordable products, quality assurance. You can count on us to work together.

Foundation Drilling

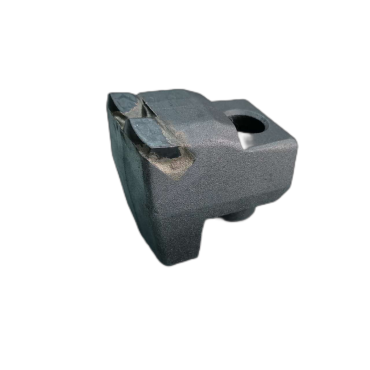

WELD-ON TEETH

DRAGON TOOTH

FLAT TEETH

ROUND SHANK CUTTER BITS

SHANK SYSTEM

SCRAPER BLADES

Road Reconstruction

Road Milling Bits

Asphalt Milling Teeth

Concrete Milling Teeth

Forestry & Recycling

MULCHERS

MULCHERS

MULCHERS

MULCHERS

STUMP CUTTERS

STUMP GRINDER TEETH

STUMP GRINDER TEETH

WOOD GRINDERS

RECYCLING

Our TEAM

Our goal is to satisfy customers by providing them with excellent service and products. We welcome feedback and suggestions from our customers, as we believe that this helps us to continually improve our service and better meet their needs.

Thank you for choosing us, and we look forward to serving you!

Foundation Drilling

SKYMECH cutting systems provide tooling and wear solutions for your foundation drills including cutting tools, tool holders, tool pullers, auger cutting tools. Achieve greater gains in foundation drilling with SKYMECH carbide solutions.

Road Reconstruction

SKYMECH cutting systems provide tooling and wear solutions for road planers .

From road planer skis, blades, cutting tools, bits, tool holders, blades,

and tool pullers, we have you covered.

Forestry & Recycling

SKYMECH is a manufacturer of tungsten carbide and tungsten carbide equipped wear parts. SKYMECH tungsten carbide tools are developed for road construction, rehabilitation and asphalt crushers, as well as with manufacturers of mulchers, wood chippers, shredders – for example for wood-and other forestry , agricultural machines. Tungsten carbide grades are matched exactly to application areas in terms of hardness and durability, ensuring high performance and break resistance. In combination with high quality steel bodies SKYMECH manufactures tool systems that provide excellent support to the performance of modern machines. A high degree of efficiency is guaranteed through the balance of wear between the tungsten carbide and the steel body, thus ensuring complete use of the tungstend carbide wear part.

FAQ

1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Yes, we have 100% test before delivery.

T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages

before you pay the balance.