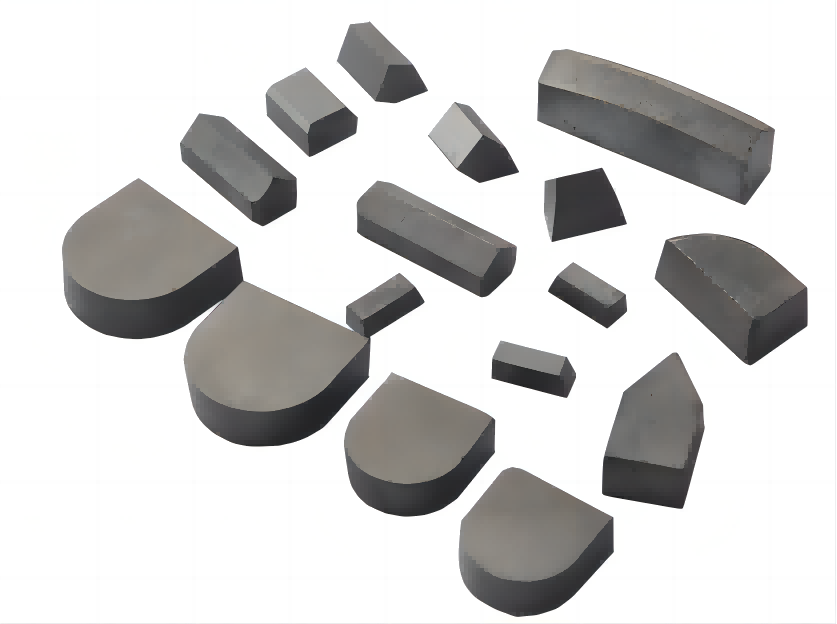

The Cemented carbide brazing plays a pivotal role in enhancing the durability and performance of wear-resistant tools utilized in various industrial applications. These tools, including shredder hammers, forestry mulcher teeth, stump grinder teeth, and woodworking cutters, rely on the unique properties of cemented carbide brazing to withstand the rigors of digging, cutting, crushing, and milling tasks.

At the heart of hardfaced carbide brazing is the bimetal structure. This structure typically comprises a hard carbide cutting or crushing component fused with a matrix of carbon steel or low alloy steel, often medium carbon steel. This combination offers several advantages, including the ability to alleviate significant stress experienced during compression bending, impacts, or alternating loads.

The hard carbide component, made primarily of cemented carbide, serves as the cutting or crushing element of the tool. Its exceptional hardness and wear resistance make it well-suited for demanding applications where abrasion and friction are prevalent. In contrast, the carbon steel or low alloy steel matrix provides the necessary toughness and support, ensuring the overall integrity of the tool under extreme conditions

The brazing process itself is a critical aspect of cemented carbide brazing, as it directly influences the performance and longevity of wear-resistant tools. A well-executed brazing process results in a strong metallurgical bond between the hard alloy and the substrate, maximizing the tool’s resistance to wear, impact, and fatigue.

In conclusion, cemented carbide brazing represents a cornerstone in the development of wear-resistant tools designed to withstand the toughest industrial environments. For many years, SKYMECH Machinery has been at the forefront of cemented carbide brazing, catering to the needs of manufacturers in diverse industries. By leveraging extensive expertise and cutting-edge technology, SKYMECH Machinery delivers high-quality brazed wear-resistant parts for agricultural and forestry machinery, waste recycling equipment, rotary excavation machinery, road milling equipment, mining machinery, and more. Through continuous innovation and a commitment to excellence, SKYMECH Machinery remains a trusted partner for businesses seeking durable and reliable wear-resistant solutions.

Tip: Carbide wear-part can be displayed on our video website on YouTube