Our advantage

Our company was founded in 2007, is a professional metal parts precision manufacturer. The fields involved include civil engineering,forestry, road construction, mining, and agricultural machinery. Forestry machinery parts mainly include Stump Cutter Teeth,forestry mulcher teeth,Carbide Beaver Teeth Four-Point Forestry Tooth.

1、One-Stop Solution

we are providing a range of services, including product design, mold design, forging molding, precision machining, Brazing and surfacing wear-resistant solutions.

2、Cutting-Edge Technology

We develop and apply cutting-edge technologies, especially tungsten carbide brazing and tungsten carbide pellet surfacing.

3、Top-Notch Quality

We strictly comply with ISO9001 standards. Control every link, and have automatic production equipment.

As one of the most professional Grinder Wear Parts manufacturers and suppliers in China, we’re featured by durable products and good service. Please rest assuredto buy high quality tree saw parts from our factory. Also, customized service is available. Our primary intention should be to offer our clientele a serious andlresponsible enterprise relationship, delivering personalized attention to all of them for Trencher Parts, Machining Parts, CNC Machining Parts.

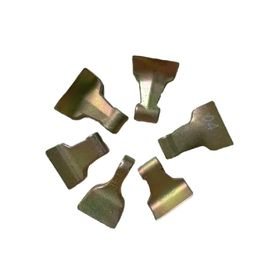

Wood Grinder Parts

Stump Grinder Parts

Mulcher Parts

Production process

Hot Die Forging, Warm Extrusion and Cold Extrusion

CNC Machining Center and Precision Machining Service

Carbide Brazing and Brazing External Processing

Tungsten Carbide Particle Surfacing