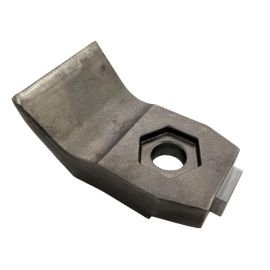

Road Milling Teeth

Name:Road Milling Bits/ Cold Planer Teeth/Round Shank Picks/Drum Cutters/Foundation Drilling Tools/Foundation Drilling Augers/Mining Cutting Tools

Compatible Brand: wirtgen/ kennametal/sandvik

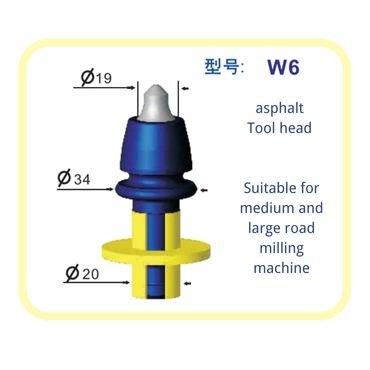

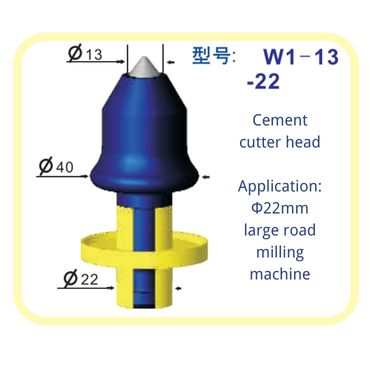

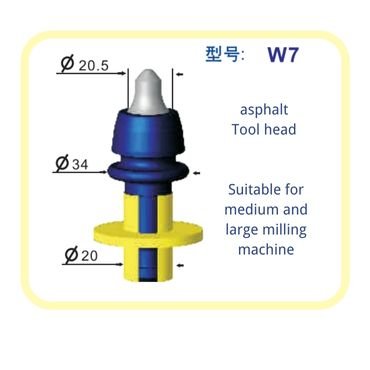

Model Number:

- For wirtgen milling teeth

cutting concrete: W1-10/20, W1-13/22W1-10、W1-13、W1-15,W7/22、W8/22

cutting asphalt: W5/20, W6/22, W6/20,W7/20, W8/20 - For kennametal

RS14、RS16、RS18 RP18、RP24、RP25、RP27、RP28 、RZ05、RZ07、RZ08、RZ19、RZ20

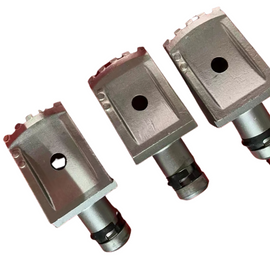

For tool holder:C10、C10LG、C10AMC、QC110HD、QC110H、KPF303R、QC100、QC110B、KPF301; - For sandvik asphalt milling teeth

Get Samples

Lead time:

| Quantity (pieces) | 1 – 50 | 50-3000 | > 3000 |

| Lead time (days) | 15 | 20 | 30 |

Payments: T/T, Credit Card,

……

……

Our Advantages Of Road Milling Teeth

- Longer service life: Our road milling teeth last 1-1.5 times longer than traditional rotary cutting teeth.

- Higher work efficiency: Our road milling teeth are 2.5 times more efficient than rotary cutting teeth.

- Energy-saving: Our road milling teeth reduce replacement needs and minimize shearer stoppage time, lowering mining costs.

- Quality standards: Our road milling teeth meet specific quality standards, including cone hardness (HRC > 65), cutting rod hardness (HRC 28°-32°C), and surface hardness (HV > 2000). We use a special heat treatment process for optimal hardness and minimal oxidation.

- Adaptation to local conditions: We offer high-strength hard rock rotary digging teeth tailored to different coal seams. This includes wear-resistant teeth for F1-F3 layers, grinding teeth for F4-F6 grade sandstone layers, and high-strength teeth for F7-F9 layers. Customizing teeth to specific coal seams helps reduce costs and improve efficiency.

- Customization support: We provide customization options for our road milling teeth. Share your samples, drawings, and product dimensions, and we’ll tailor our products to your requirements.

Applicable to the following areas

Road Construction: Road milling tines are used in road construction projects, including the milling and grading of new roads. They chip away at uneven pavement surfaces to ensure the road is smooth and within specifications.

Road Maintenance: Road milling teeth are also very important for maintenance and repair work on existing roads. They can be used to remove damaged or worn layers from road surfaces so they can be repaired and repaved.

Bridges and Tunnels: Pavement milling tines are also used for pavement milling and maintenance of bridges and tunnels to ensure the smoothness and safety of these important infrastructures.

Airport Roads: Airport runways and taxiways also require regular maintenance and repairs. Road milling teeth are used to maintain the smoothness of airport roads and ensure aviation safety.

City Streets and Highways: City streets and highways require regular maintenance and repairs to ensure traffic safety and comfort. Pavement milling teeth are used to remove damaged pavement layers and smooth the road surface.

Shipping & Packing

Size Of Road Milling Bits

Common size:22cmasphalt milling teeth、20cmroad milling teeth

High Quality Cold Planer Teeth Removal Tool

What Is Road Milling Teeth?

Road milling teeth are cutting tools used on road milling machines to repair and resurface roads. They are made of carbide or high-speed steel and have a tapered or spherical head with multiple cutting teeth. These teeth remove old pavement material, like asphalt concrete, to create a smooth surface for laying new pavement. The design and selection of road milling teeth depend on different application scenarios and requirements.

Why SKYMECH Road Milling Teeth?

We are a manufacturer specializing in the production of wear-resistant parts for agricultural, construction engineering, and mining equipment. With 17 years of industry experience, we have been dedicated to providing our customers with high-quality products tailored to their specific needs and requirements.

- High performance of wear-resistant parts: Our wear-resistant parts are crafted using Tungsten Carbide or PDC technology, making them 3-5 times more durable than regular products. This exceptional durability significantly extends the lifespan of the parts, reducing maintenance and installation costs, as well as overall purchase expenses.

- Competitive price: As a direct source manufacturer, we benefit from a natural cost advantage throughout the entire production process, from raw materials to casting, processing, and heat treatment. This enables us to offer our customers competitive pricing without compromising on the quality of our products.

- Fast delivery: We understand the importance of timely delivery for our customers, especially when urgent stock replenishment of wear-resistant parts is required. Our fast delivery time of 10-15 days ensures that your waiting time is greatly reduced. For regular orders, our normal delivery time is 15-20 days, providing our customers with the flexibility they need.

We firmly believe that our products and services can bring great value to your business. We would be delighted to discuss further details and address any inquiries you may have.

You May Like

FAQ

You can contact us at any time if you have questions about asphalt milling machine teeth or other products.

Yes, we are the source manufacturer here. As the source manufacturer, we personally purchase raw materials, and then strictly control the production link, quality inspection link and delivery link to ensure that the products can be delivered to customers with good quality and quantity.

If you have samples, you can provide them to us. We can test your samples through the equipment and then draw the drawings.

We can provide a small number of free samples, and customers bear the freight.

All our products are tested before delivery. If the buyer needs the test report, we can provide it. Including the raw materials used in this product, these can be detected.