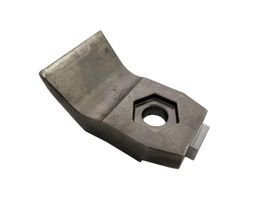

Tana rotor teeth with carbide overlay

SKYMECH supplies forged rotor teeth for Tana with high and consistent quality for carbide overlay.

Tana rotor teeth with carbide overlay

Type: Rotor Knives / Teeth

Material: Alloy steel add carbide overlay

Options: without hard surfacing

Feature: Dule life, Continue Shredding.

Base Length: 106 mm Base Width: 68mm Weight:2.4~2.45kgs

Thread type:without thread

Fitting bolt size,:24mm

Suitable for C and D Series TANA 440 shredders

Get Samples

Lead time:

| Quantity (pieces) | 1 – 2 | 500-1000 | > 1000 |

| Lead time (days) | 15 | 35 | 40 |

Purchase details

Payments: T/T, Credit Card,

……

……

Advantage of Rotor teeth with carbide overlay

Core competitive advantage:

Starting from processing customized parts, it has deepened into forging and carbide brazing, manufacturing and research and development, and has touched the bottom line of the industry’s cost structure (raw materials and processing costs)

- Exceptional Durability: Our wear-resistant parts are crafted using all-hard alloy teeth knives, resulting in a service life that is 10 times longer than steel counterparts.

- Extensive Manufacturing Experience: With nearly 20 years of professional manufacturing experience, we possess the expertise and knowledge to deliver high-quality products.

- OEM Manufacturing: We offer OEM manufacturing services, accepting orders based on drawings or samples to meet specific customer requirements.

By leveraging these core advantages, we are committed to providing our customers with top-notch products that excel in quality and durability.

Production process for Tana rotor teeth

Hot forging, produce stronger teeth body,Four column structure hydraulic press,fuselage stability, anti – biased load ability,high stamping precision.

CNC machining is the process in which computer-controlled machines remove material from a workpiece to create precision parts, here used to control size

Carbide particle surfacing(carbideoverlay): Layering carbide particles onto a substrate using welding process for enhanced hardness and wear resistance.

- DISCLAIMER

All brands mentioned on this website, including Tana, are registered trademarks. Any references to these brand names on this website are solely intended for the purpose of distinguishing the intended use of the products. Our company and this website do not have any sponsorship or authorization from the aforementioned brands, and we do not use or imply the use of these brands for any commercial purposes. The products showcased on our website are not endorsed or affiliated with the mentioned brands.

Details Of Rotor Knives / Teeth

Our aftermarket replacement for the Rotor Knives / Teeth is designed specifically for the aftermarket market, offering users an affordable alternative to meet their waste processing equipment needs.

Crafted from high-quality materials and precision-engineered, this hammer/teeth component replacement ensures performance and durability comparable to OEM products. Whether it’s in waste or wood, grindering, our replacement provides stable and reliable cutting performance, helping users maintain productivity.

As a choice for the aftermarket market, our Tana rotor teeth component replacement offers excellent value for money, providing users with a reliable solution while reducing maintenance and repair costs.

Related Products

FAQ

It is very attractive to have a replacement with 90% original quality for 50% of the price.

If there is a quality problem with our product,contact your sales and we will deal with it as soon as possible

Ningbo, Zhejiang, China. Make an appointment with us in advance, you are welcome to visit our factory at any time.

Within 15-35 days after we confirm your request.

T/T, L/C, cash, Western Union are all ok, if you have other payment methods, please contact me.